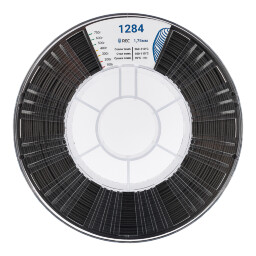

FormaX plastic X-line 1.75мм

Features

- Material

- ABS+CF15

- Thread diameter

- 1.75 мм

- Net weight

- 750 g

- Length

- 280 m

- EAN

- 4627095775482

- Made in

- Россия

Features

- Material

- ABS+CF15

- Thread diameter

- 1.75 мм

- Net weight

- 750 g

- Length

- 280 m

- EAN

- 4627095775482

- Made in

- Россия

Можно выбрать набор (5) со скидкой

- ForMAX- engineering thermoplastic based on ABS with the addition of carbon fibers, capable of withstanding heavy loads and high temperatures, there is practically no shrinkage when printing.

For the production of carbon fiber yarn, we use tiny fibers that are introduced into the base material to improve its properties. FORMAX can be purchased with a carbon fiber filler. These fibers are extremely strong, and cause an increase in the strength and stiffness of the filament. This also means that parts printed on a 3D printer will be much lighter and more stable in size, since the fibers will help prevent the part from shrinking as it cools. The print settings, such as print temperature, print speed, table adhesion and extrusion speed, will be very similar to the usual settings used for the main material to which the fibers were added - in this case, the ABS material was taken as the basis. However, due to the added fibers, the resulting FORMAX filament is more likely to clog the printer with standard ABS settings, so it is necessary to make adjustments to the printer settings, and special equipment may also be required to avoid damage to the printer.

Formax as opposed to abs

Tips from REC by Formax

Advantages:

Increased strength and rigidity

Very good dimensional stability

Lightweight

Excellent final surface (hidden layers)

Disadvantages:

Abrasive and requires a hardened steel nozzle

The thread is slightly more "fragile"

The probability of nozzle clogging is slightly higher

These tips will help you reduce the likelihood of common 3D printing problems associated with carbon-filled filament, such as clogging and nozzle wear.

Replace with a steel nozzle

The carbon fibers in FORMAX can be extremely abrasive. In many cases, carbon fibers are actually harder than the brass nozzles used in most 3D printers, so trying to print with this material using a standard nozzle can damage the printer. Instead, it is necessary to switch to a nozzle made of hardened steel. The nozzle material will resist additional wear of the fibers, however, such nozzles tend to be less heat-conducting than their brass counterparts. Therefore, depending on the printer, you need to take into account that with the change of the nozzle material, you need to change the printing temperature as well. Reducing the speed of rotation of the blowout (fan) can also be useful to prevent thermal problems with steel nozzles.Adjust the parameters of the retractor to avoid blockage

Since the FORMAX thread is full of small fibers that do not melt, the probability of clogging the nozzle is significantly increased compared to conventional ABS. We recommend reducing the retraction or completely disabling it, since the return of the rod can increase the accumulation of fibers inside the extruder assembly. Some slicers have a great feature “avoid crossing contours when moving”. It will allow you to move the extruder inside the part that you are printing.Speed is lower - stability is higher

For better results, use a lower print speed for FORMAX, since the extruder will experience less load, and therefore it is more likely to be able to push a small blockage through the nozzle if it suddenly begins to form. Try reducing the print speed by 25-50% to see which value is best suited for your specific 3D printer model. If after making these changes you are still experiencing difficulties in printing, then we have a “support " section.Guides for the rod from the coil to the extruder

The carbon fiber-filled FORMAX thread is slightly more "fragile" than a regular ABS thread, and it can break if its path passes through narrow corners, or it can completely wipe the edges of the printer frame. Make sure that the entire path of the rod, from the coil to the nozzle, consists only of gentle bends, without sharp turns or areas where the thread will stretch along the surface. Use guide fluoroplast tubes or other suitable tubes. All this will help to reduce the probability of breaking the thread.

Top TipsA nozzle with a larger diameter (0.5 mm or more) is less likely to become clogged, since the fibers will pass through the larger nozzle hole much more easily.

If the nozzle seems clogged immediately after printing the first layers, try increasing the height of the first layer. If the nozzle is too close to the table, this will create increased pressure in the nozzle when printing the first layers, which can lead to the accumulation of fibers and temporary clogging of the nozzle.

ApplicationIt is perfect for printing almost any product: functional models, prototypes, high art, decorative objects, drone parts, gears, molds for molding and much more.

Additional characteristics:

Glass transition temperature-105 °C

Surface resistance - >109

Print Settings Nozzle temperature 274°C Table temperature 95°C Blowing not desirable Recommended adhesive The3D Glue Min. nozzle diameter 0.3 mm Comparison of materials in a simple way and for professionals

For more information about the characteristics, advantages and parameters of printing with Formax-plastic, you can read in article

Общие характеристики

Плотность 1,11 г/см3 Температура эксплуатации от -60°С до +105°С Температура размягчения н/д Страна производитель Россия Механические характеристики

Ударная вязкость по Шарпи 141.52 кДж/м2 Прочность при растяжении вдоль слоев 35,52 МПа Модуль упругости при растяжении вдоль слоев 3,21 ГПа Прочность на изгиб 74,8 МПа Модуль упругости на изгиб 3,767 ГПа Максимальная нагрузка на изгиб 117,6 Н Прочность при растяжении поперек слоев 24,65 МПа Модуль упругости при растяжении поперек слоев 2220 МПа Максимальная нагрузка на растяжение 1,52 кН Прочность на сжатие 108,8 МПа Модуль упругости на сжатие 1,774 ГПа Максимальная нагрузка на сжатие 13,6 кН Коэффициент удлинения 2,1% Биоразлагаемость н/д Предел текучести при растяжени и при температуре 23°С н/д Прочность при изгибе 2,8 мм/мин. 23°C н/д Твердость по Шору (шкала D) н/д Масло-бензостойкость (максимальное изменение формы за 24 часа) н/д Кислородный индекс, %O2 по ГОСТ 21793-76 н/д Массовая доля золы по ГОСТ 15973 н/д Электрические характеристики

Удельное электрическое сопротивление на постоянном токе 9,1х1014 ОМ/см Диэлектрическая проницаемость на постоянном токе 3,82 Диэлектрическая проницаемость на частоте 50 кГц 3,54 Тангенс угла диэлектических потерь на частоте 50 кГц 0,0038 Электрическая прочность 14,5 кВ/мм Транспортные характеристики

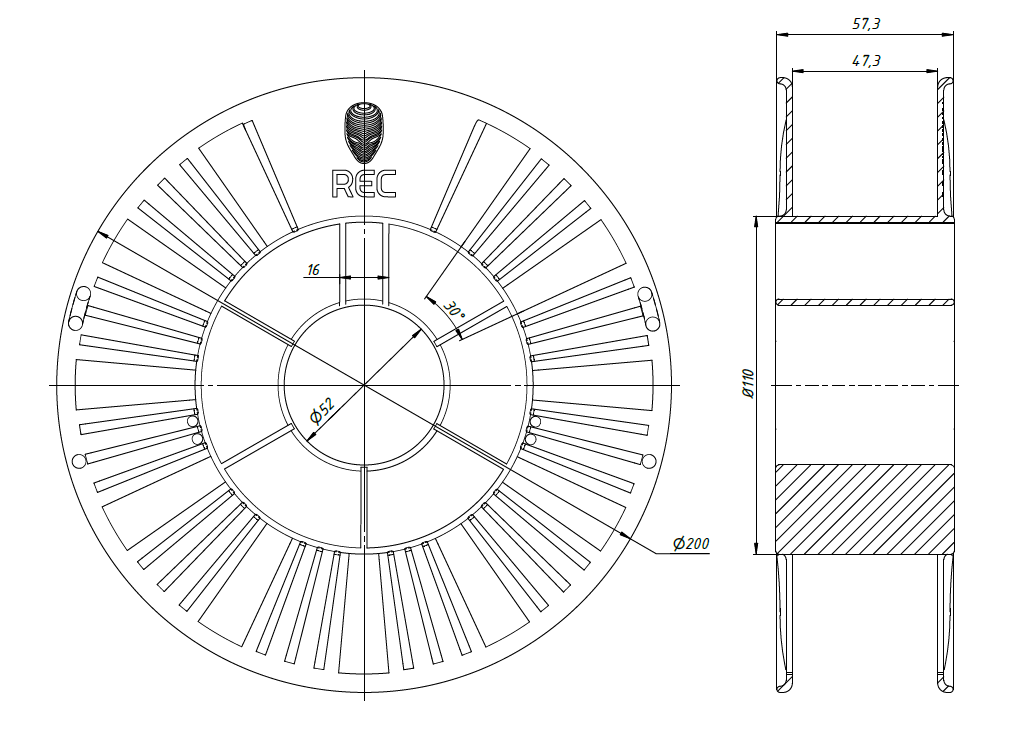

Габариты упаковки 210х225х70 мм Вес нетто 750 грамм Вес брутто 1.1 кг

Loading data...

Loading data...- РЕЗУЛЬТАТЫ ИСПЫТАНИЙ:

На ударную вязкость по Шарпи На изгиб На разрыв вдоль слоев На разрыв поперек слоев На сжатие*все испытания проводились на напечатанных образцах с толщиной слоя 0.2мм

Сертификаты безопасности