3D post-processing

Consultations on post-processing are free of charge:) call us! +7 (499) 2882726

Post-processing of 3D models is an effective way to eliminate defects that may occur when printing a product. Attachment points, roughness, unevenness, layering-getting rid of all the shortcomings will allow you to get a smooth and neat object ready for use.

Basic post-processing methods

To date, there are several post-processing methods that are selected by specialists depending on the type of product:• Manual.

• Chemical.

• Use of specialized equipment.

• Coating application.

Gluing and assembling

Gluing parts is a common task when creating complex, large-scale objects, the printing of which is difficult or impossible due to its dimensions.

Prices for gluing and assembling

| Gluing and assembling | 100rub per joint |

|---|

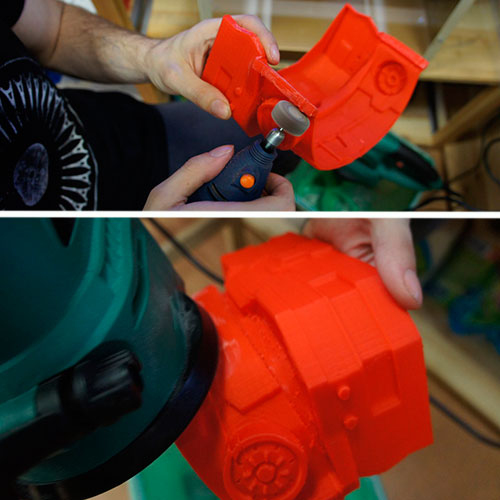

Mechanical smoothing

The mechanical processing of printed products is carried out in various ways, starting from an ordinary skin and ending with a grinding machine. As a rule, it is used for complex products where high accuracy is required. During manual processing, specialists use special tools that can eliminate external defects of the finished product.

Fur prices. processing

| Fur. processing | 1500rub per hour |

|---|

Chemical smoothing

Chemical processing is the process of processing a printed part with an appropriate chemical (acetone for ABS plastic, methylene chloride for PLA plastic). This process is more suitable for giving the model a gloss and eliminating minor flaws. The main essence of chemical processing is the use of reagents or solvents. A very important nuance that affects the efficiency of the processing process is the selection of a particular material. Depending on the type of plastic and the general characteristics of the product, it is necessary to use a certain type of reagent.

Prices for chemical products. processing

| Chemical treatment | from 300rub for one item |

|---|

Painting

Priming - finishing preparation of surfaces before painting. A filling primer is applied to hide all micro-pores and irregularities.

Putty is the process of leveling a part, filling seams, depressions and surface roughness. As a rule, it allows you to hide the layering of the surface after printing, unlike drilling.

Painting - applying layers of acrylic paint, it is allowed to use up to 3 colors for one part.

The varnish is used to protect the painted part from external influences, the varnish can be glossy or matte.

The use of specialized equipment - to achieve the maximum processing effect, special installations can be used. Processing 3D models after printing using such equipment allows you to get rid of all kinds of defects.

Coating - an effective method is the application of coatings (for example, metallization or epoxy coating). Such processing after.

Prices for painting

| Putty + primer | from 500rub |

|---|---|

| Painting | from 300rub |

| Lacquer | from 250rub |

REC Company has been providing 3D printing services and other accompanying services related to additive technologies for more than 5 years. The 3D post-processing performed by our specialists meets both the standards accepted in the industry and the wishes of customers. In our activities, we use high-quality materials and modern equipment, thanks to which the result of our work is always at the highest level.

Do you need 3D printing post-processing? Contact the company REC!